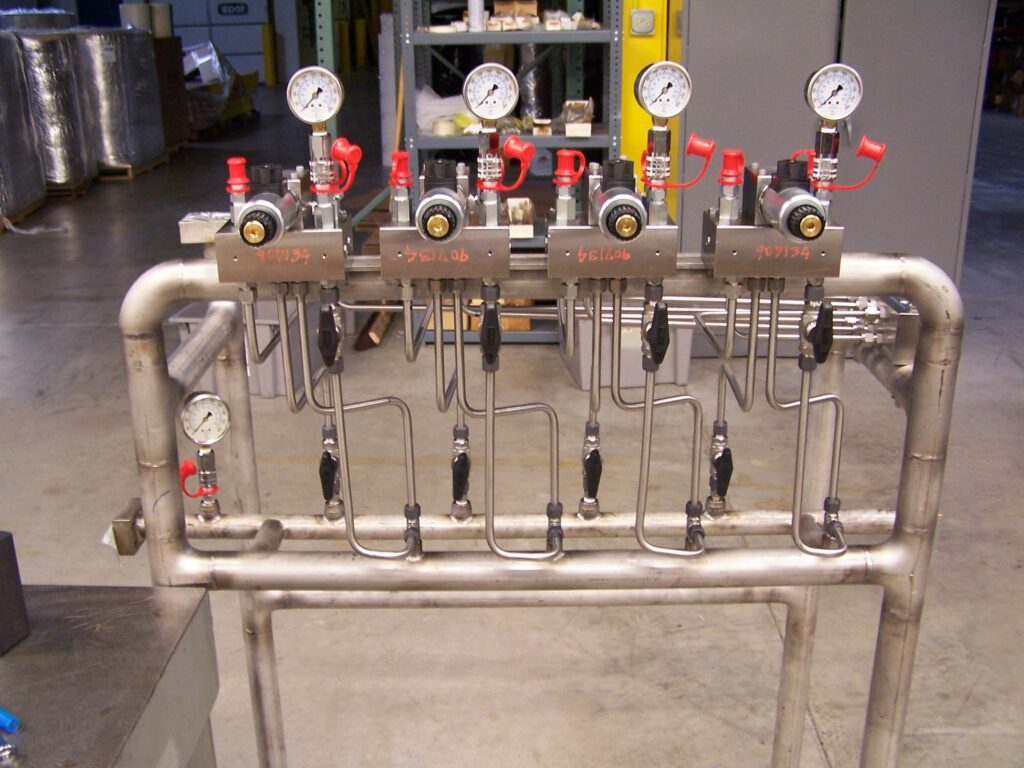

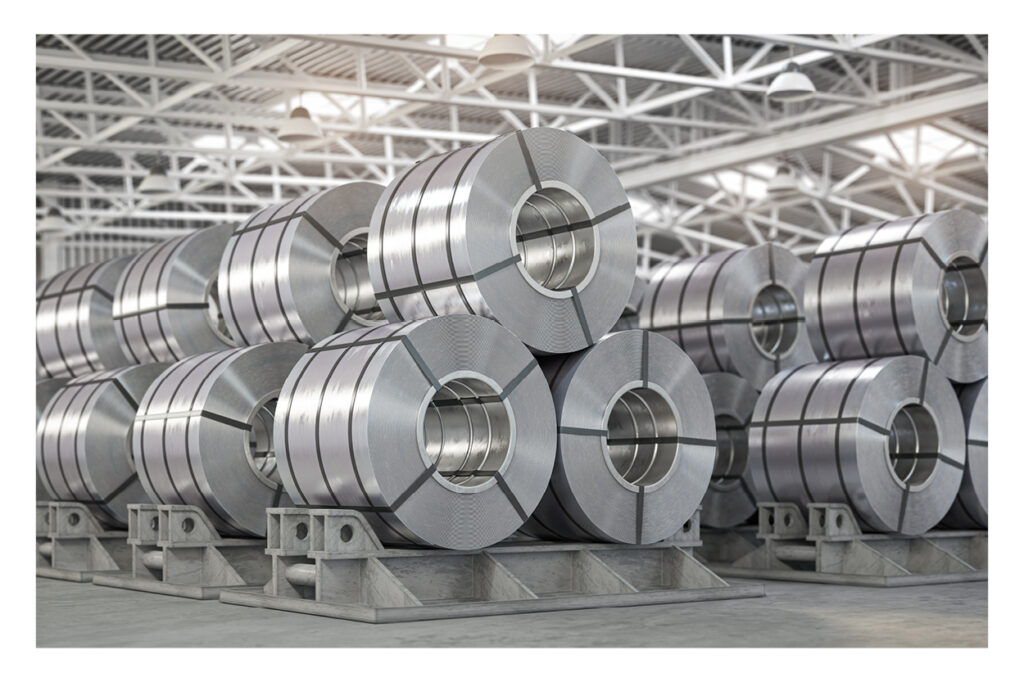

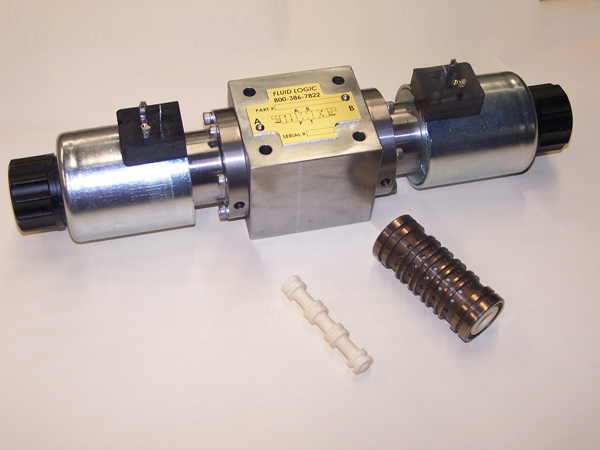

Fluid Logic is one of the leading manufacturers of standard hydraulic valves and systems for high water based and low viscosity fluids. However, we are rapidly gaining attention for their ability to develop custom designs and manage the production of large-scale projects for critical applications. The valve stand featured here required them to incorporate a standard P&T manifold billet and NFPA pattern valves, designing it to meet size restrictions as detailed by the customer. Constructed from salt bath nitriding carbon steel, ceramics and stainless steel, their design offers superior protection against corrosion and failure resulting from high pressure. The valve stand also meets requirements of the metal processing industry for handling 95/5 or other high water based fluids. To maintain Fluid Logic’s reputation as a manufacturer of zero leak technology, we perform rigorous testing for functionality along with a dimensional inspection on each made part. These stands are primarily used in steel rolling processes and aluminum mills on 95/5 or water glycol systems Incorporate a common P & T manifold billet and utilize NFPA pattern valves to build the most compact stands Salt Bath Nitriding carbon steel, stainless steels and ceramics Fluids: 95/5 or other high water based fluids